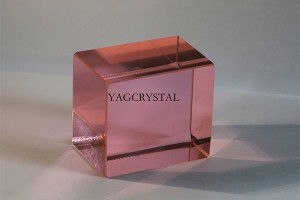

Isku-xidhka Crystal- Farsamada Isku-dhafka ah ee Crystals Laser

Sharaxaada Alaabta

Muhiimadda codsiga tignoolajiyada isku-xidhka ee kiristaalo laser waxay ku jirtaa: 1.Miniaturization iyo is-dhexgalka aaladaha / nidaamyada laser, sida Nd: YAG / Cr: YAG bonding ee soo saarista lasers-ka ee Q-switched microchip; 2. Hagaajinta xasiloonida kulaylka ee ulaha laysarka Waxqabadka, sida YAG / Nd: YAG / YAG (taas oo ah, bonded YAG saafi ah si ay u sameeyaan waxa loogu yeero "dhammaan cap" ee labada daraf ee usha laser) si weyn u yaraynaysaa kor u kaca heerkulka ee wejiga dhamaadka Nd: Usha YAG marka ay shaqaynayso, inta badan loo isticmaalo qalabka korontada adag laser-state.

Shirkaddayada YAG taxanaha ugu weyn ee alaabada crystal bonded waxaa ka mid ah: Nd: YAG iyo Cr4+: YAG bonded ulo, Nd: YAG bonded YAG saafi ah labada daraf, Yb: YAG iyo Cr4+: YAG bonded ulo, iwm .; dhexroor ka Φ3 ~ 15mm, dhererka ( dhumucdiisuna waxay ka 0.5 ~ 120mm , sidoo kale waxaa laga baaraandegi karaa galay strips square ama go'yaal laba jibbaaran.

crystal bonded waa shey isku daraya crystal laser leh hal ama laba maaddooyinka substrate-ka isku midka ah ee saafiga ah iyada oo loo marayo tignoolajiyada isku xidhka si loo gaaro isku darka xasilloon. Tijaabooyinku waxay muujinayaan in kiristaalo-ku-xidhka ay si wax ku ool ah u yareeyn karaan heerkulka kiristaalo laysarka oo ay yareeyaan saamaynta saamaynta lenska kulaylka ee ay keento qallafsanaanta wejiga dhamaadka.

Astaamaha

● Lensiga kulaylka oo yaraada oo ay sababto qallafsanaanta wejiga dhamaadka

● Waxtarka iftiinka-ilaashka oo la hagaajiyay

● Kordhinta iska caabbinta heerka waxyeelada sawirka

● tayada wax soo saarka laysarka oo la hagaajiyay

● Tirada la dhimay

| Fiican | <λ/10@632.8nm |

| Tayada dusha sare | 10/5 |

| Isbarbar yaac | <10 ilbiriqsi |

| Toosannimada | <5 daqiiqo |

| Chamfer | 0.1mm@45° |

| lakabka dahaarka | dahaarka AR ama HR |

| Tayada indhaha | Fargelinta faragelinta: ≤ 0.125/inch Faragelinta faragelinta: ≤ 0.125/inch |